The Heat is On

Spray Foam Magazine – Fall Issue 2021 – A heated driveway has a similar concept to underfloor heating—tubes that run beneath the surface. Warm water and usually some kind of antifreeze is then forced through the tubes to keep the driveway at the perfect temperature and thus preventing the accumulation of snow and ice with the driveway being kept at a temperature just above freezing. The tubing usually goes through a boiler, often situated in the garage, and helps maintain a consistently warm temperature.

Based In Abbotsford, British Columbia, Canada, spray foam insulation company, Newco Enterprises Ltd. was scheduled for a local job by Sonbuilt Custom Homes Ltd. which is owned and run by Jonathan and Carmen Zerkee. The Newco crew loaded their custom built 20 ft cargo trailer including a Graco Reactor two E-30 proportioner (260 ft of hose), Probler P2 Elite GlasCraft spray gun, 40kw generator and air compressor and dryer to the job site.

Sonbuilt Custom Homes is a Net Zero, Certified R-2000 builder, and Mike Holmes Approved Builder. They pride themselves on specializing in high efficiency custom homes with a high-performance finished product for all their clients. They also hold all of their contractors to the highest standards when building these luxury homes in the Fraser Valley, British Columbia area. Installing heated driveways for their client’s helps preserve their driveways surface by protecting it from the freeze and thaw cycle and therefore cracks and crumbling are reduced.

Sonbuilt Homes installed a hydronic system which included glycol radiant, also known as antifreeze and heated pipes in this client’s driveway. They also required Newco Enterprises to insulate the ground to optimize the efficiency of the boiler. The installation did not require city inspection and was specified by the builder to give the best thermal efficiency for their client.

The preparation of the base is crucial when it comes to a heated driveway, so before the job could commence on the approximately 2,000 sq ft of driveway, the builder had to prep the ground with 3/4 inch of crushed gravel and compact with a plate tamper.

The use of salt and or grit on driveways can be damaging to the driveway's surface and can even cause harm to plants and wildlife when it runs off into streams or rivers nearby, so many see the heated driveway as not only a convenience, but also ecologically viable.

The crew poured a two foot wide smooth finish concrete edging along the driveway area. The Newco crew then spray foamed within the concrete edging, applying directly to compacted gravel. A wire mesh/rebar was then placed on top of the spray foam. Once this was completed the plumbers came to install the radiant heat pipes on top of wire mesh/rebar, which basically attaches the pipes onto wire mesh/rebar. The pipes were then pressure tested to ensure there were no leaks. The last step was then to pour concrete on top of the driveway. In this application they decided on a stamped concrete design, which is commonly referred to as patterned concrete or imprinted concrete.

To complete the heated driveway installation, foam insulation was applied over a layer of compact gravel before radiant heat pipes were installed to rebar.

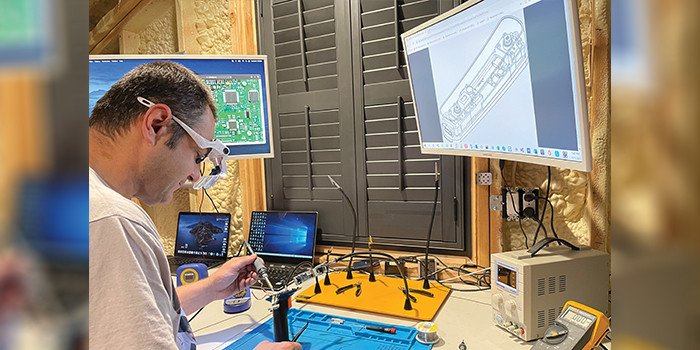

Newco Enterprises Ltd., is family run and has been in business for over forty years. Derrick Larochelle and his father John were working this job with Derrick being the installer and John his assistant. Their morning consisted of a Job Hazard Assessment to identify the immediate hazards and they also completed a daily inspection of all their PPE to ensure that they were in perfect working condition

Derrick wore a full-face respirator, supplied fresh air, long sleeve apparel and CSA approved steel toed boots with non-permeable gloves and his father John, who was not in the immediate work area, wore a half-mask respirator with OV/P100 cartridges and additional PPE attire.

Newco Enterprises applied three inches of SES Nexseal 2.0 CDN (HFO) and used around two sets of the foam which offers a higher PSI compression strength than regular Styrofoam board stock.

Additionally, it provides a monolithic installation, rather than individual boards, and therefore provides a better ground seal. The weather was a toasty 86° F which was perfect for the Newco crew and helped maximize their yields.

Heating a driveway may seem like an indulgence but many contractors in northern regions of the U.S. and Canada are beginning to install these heated driveways in newly constructed houses as standard features. However, this practical luxury is becoming increasingly popular with many homeowners of older properties who have their driveways replaced and a heated one installed. Living in cold climates these homeowners are used to shoveling snow and scraping off ice from their driveway but if they have a heated driveway installed, they can save time, driveway damage, and general annoyance and are therefore willing to invest.

Disqus website name not provided.