Dow Foam Dispensing Tool “Eliminates” Installation Woes with Customizable Solutions

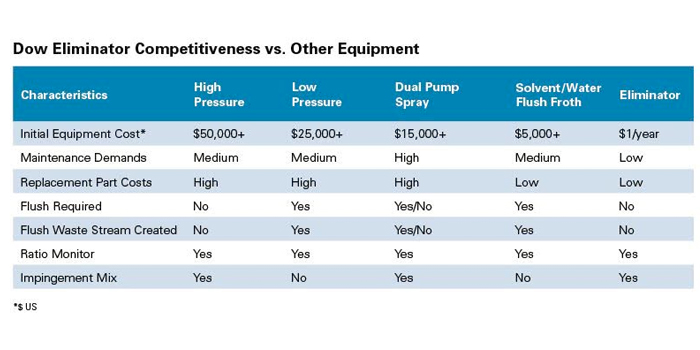

MIDLAND, MI – April 28, 2016 – Dow Polyurethanes is helping manufacturers increase production of high-performance polyurethane doors while keeping investments low. As demand for new energy and cost-efficient doors increases, Dow is showcasing how the one-of-a-kind DELTA THERM™ Eliminator Dispensing Gun can provide solutions at IDAExpo 2016, currently ongoing in Las Vegas.

Compact and lightweight, the Eliminator enables the most accurate and reliable metering, mixing and dispensing equipment to produce a superior rigid polyurethane foam.

“Manufacturers already know that polyurethane foam is one of the best insulation materials available to help achieve energy-efficiency targets,” said Robert York, market manager for Dow Polyurethanes. “Installation, however, can be tricky without the right tools. The DELTA THERM Eliminator Gun helps reduce the investment risk while enabling an easy installation process and expert service and training.”

How It Works

The Eliminator is a tool that uses an impingement mixing technology in which the “A” and “B” polyurethane components are automatically mixed and dispensed through the gun nozzle. The self-cleaning shut-off mechanism eliminates the need for hazardous solvents or hot water flushing. This results in no hazardous waste handling or disposal problems. The Eliminator has 6 pound – 80 pound throughput ability.

RELATED Dow Polyurethane Technologies Enable Code-Compliant Insulation Solutions in North America , Dow Announces Settlement in Urethanes Class Action Litigation, Project to Develop Recyclable Polyurethane Foam Wins $10K Dow Sustainability Innovation Student Challenge Award

The unique features of the DELTA THERM Eliminator Dispensing Gun provide a number of key benefits for manufacturers, including:

· Low cost equipment is available to customers through an authorized lease agreement.

· Ease of use enabled by removing the complexity of traditional foam dispensing equipment.

· Externally adjustable flow controllers allow the chemical flow rate to be set through in-line flow controllers that are easily adjustable, enabling quicker and cleaner adjustments to achieve desired chemical foam ratios.

· Internally heated hoses allow the components to be heated quickly and evenly with an auto shut-off to avoid overheating.

· Multi-shot timer enables users to program sequences for timed shots for added convenience.

· Ratio monitoring enables data from the “A” and “B” components to be monitored and data can be downloaded to better calculate usage of VOC-emitting products for reporting purposes.

· Customizable solutions means customers have a wide range of froth systems available from Dow for use in different applications.

· Customer service from Dow provides training and assistance in testing, operation, maintenance and repairs, as well as piping/systemlayout to customers.

“Combining outstanding technical service and chemistry performance all wrapped into an improved equipment option means our customers have access to the best resources, expertise and products that lead to success,” said York.

DELTA THERM Eliminator Dispensing Gun can be used in a number of applications, including commercial refrigeration units, insulated transportation, insulated panels and doors and marine floatation.

About Dow Polyurethanes: Dow Polyurethanes develops and delivers a broad portfolio of technologies and customized solutions to customers in a variety of industries, and applications ranging from energy-efficient insulation materials, to industrial and infrastructure solutions, to consumer comfort solutions in flooring, furniture, bedding and footwear. The business manufactures and sells key chemical components as well as fully-formulated polyurethane systems for rigid, semi-rigid and flexible foams, and coatings, adhesives, sealants, elastomers and composites. Dow is the world's largest producer of propylene oxide (PO), propylene glycol (PG), and polyether polyols, and is a leading producer of quality aromatic isocyanates, such as MDI. Striving to meet the specific needs of its customers in their local geographic regions, Dow Polyurethanes operates a global network of production sites and systems houses, as well as innovation and service centers. The business has an ongoing initiative to lead the industry in providing high-performance products that meet critical market needs and contribute to a more comfortable, healthier and resilient society. For more information, visit www.dowpolyurethanes.com and follow us on Twitter and LinkedIn.

About Dow: Dow (NYSE: DOW) combines the power of science and technology to passionately innovate what is essential to human progress. The Company is driving innovations that extract value from material, polymer, chemical and biological science to help address many of the world's most challenging problems such as the need for clean water, clean energy generation and conservation, and increasing agricultural productivity. Dow's integrated, market-driven, industry-leading portfolio of specialty chemical, advanced materials, agrosciences and plastics businesses delivers a broad range of technology-based products and solutions to customers in approximately 180 countries and in high-growth sectors such as packaging, electronics, water, coatings and agriculture. In 2015, Dow had annual sales of nearly $49 billion and employed approximately 49,500 people worldwide. The Company's more than 6,000 product families are manufactured at 179 sites in 35 countries across the globe. References to "Dow" or the "Company" mean The Dow Chemical Company and its consolidated subsidiaries unless otherwise expressly noted. More information about Dow can be found at www.dow.com.

Disqus website name not provided.